Roasting

[Commitment No. 1] The secret to its tastiness is direct roasting

Roasting over direct heat is an ideal way to effectively bring out the sesame's fragrance and lock in the delicious taste.

Roasting methods can largely be divided into two types: hot-air roasting and direct roasting. The first method directly applies hot air to the sesame and is extremely efficient. However, both the surface and center of the sesame are heated evenly. On the other hand, direct roasting involves heating a pot that contains the sesame. The sesame is not heated evenly, so the sesame's surface hardens while the center becomes tender. Most ordinary “ground sesame” products are roasted with hot air, but Onizaki's sesame products are all roasted over direct heat.

Fragrance is released from the sesame's outer skin when it's heated. At Onizaki, we bring out this fragrance of sesame to the utmost through the method of direct roasting, which involves heating the sesame surface at high temperatures.

Meanwhile, the sesame's tasty ingredients are located in its center. Since this portion is not strongly heated in direct roasting, its tasty flavor is preserved. In other words, the sesame's fragrance is brought out by strongly heating the surface, while the tasty ingredients remain trapped in the center, producing ideal sesame.

The most important point in direct roasting is controlling the temperature of the roasting machine. The machine's temperature is easily affected by the temperature and humidity of the room, atmospheric pressure and other factors. However, the new factory completed in June 2009 makes possible an extremely high level of air tightness in the room. As a result, we now have more control over air temperature than ever before, which has enabled the production of even tastier sesame.

Hot air roasting

By applying heat evenly, neither the skin's fragrant ingredient, named pyrazine, nor the center's tasty ingredients react.

Direct roasting

By applying heat directly, the skin's fragrant ingredient pyrazine reacts strongly, releasing a pleasant aroma.

| Hajime Sato, Sesame Roasting Meister, Director of “Taste”To allow customers to enjoy the most excellent sesame | ||

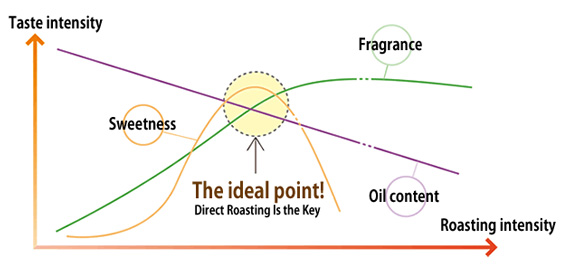

| What makes our roasting method special is that we bring out the sweetness, fragrance and flavor inherent in the sesame to the utmost. A certain amount of heat must be applied to bring out the sesame’s sweetness, yet too much heat reduces the sweetness. This trait makes the process of roasting sesame extremely difficult. I am committed to delicately adjusting the temperature when roasting sesame and bringing out its sweetness to the utmost, and I will to continue to roast sesame which customers find truly tasty. |

|

|

| Hajime Sato With Onizaki since 1993 |

||

| There is an ideal point for tasty sesame in direct roasting. |

|

| Direct Roasting Is the Key | ||

|

All of Onizaki’s sesame is roasted over direct heat, and adjustment of the flames is crucial for this roasting method. If the heat is too strong, the sweetness and flavor will decrease. If it is too weak, the sesame’s richness and fragrance will not be brought out. Employees in charge of roasting adjust the heat in units of millimeters to produce roasted sesame in its ideal condition in terms of fragrance, sweetness and oil content. As a result, the most excellent sesame is produced.

This heat adjustment is not something anyone can do. Only artisans who have received long-term training by the “Sesame Roasting Meister” – Onizaki’s Director of “Taste” – and who have passed a strict exam can be responsible for adjusting the heat. |

|

| 24-Hour Taste Management | ||

|

Roasting is a 24-hour process during which employees who are experts in the field constantly manage the taste. This is because once the roasting machine is heated, the taste is more easily stabilized by roasting continuously for long periods of time.

Furthermore, employees in charge of roasting taste the roasted sesame every two hours to check whether tasty sesame is being constantly roasted. Moreover, the sesame is naturally cooled for more than 16 hours after roasting, and the taste of sesame at room temperature is also confirmed. This is because sesame at room temperature is used during product processing, and thus the final determination of whether it passes is conducted by using sesame at room temperature. In this way, only sesame which has passed rigorous inspections is sold as products. |

|

>> Click here to see videos on the pounding and packaging processes